YLT Series Cold Forming Elbow Machine is designed for manufacturing R=1.0D & R=1.5D elbows with diameter from 1/2" to 32" of stainless steel,carbon steel, alloy steel and some kind of copper steel. Complying with standards of ASME B16.9, ASME B16.11,GB12459,JIS, DIN and GOST, the products are wildly used in industries of Petrochemical, Oil and Gas pipeline, Electricity and Foods etc.

Main features are as follows:

1、Two kinds of frame design: integrated frame and four column type. Making heat treatment for machine body to release welding stress.

2、The proportional logical circuit hydraulic system running with servo motor makes the machines energy saving, low noise, stable operation and long life span.

3、Application of PLC with touch screen realizes storing cold forming parameters (forming speed, pressure and cycle time etc) in the centralized PLC system by touch

screen. Human- computer interface makes operation very easy.

4、Three kinds of working modes including Manual, Semi-Automatic and Automatic, which can be exchanged easily.

5、Electric and hydraulic system use high quality spares parts which are imported from Germany, Japan, Italy and Taiwan to ensure best running performance.

6、Special designed molds location devices realize more convenient molds assembly. It saves lot of time and labor cost on molds and mandrel change.

7、Elbow can be formed in one time, shape calibration will be no need. Suitable for mass production with highest efficiency.

8、The hydro-forming elbow machines have protective fence and the safety interlock to ensure the operation safety. The machine functions can be continuously

monitored automatically to ensure safety work.

9、The special structure of the pushing heads and pushing rods are designed according to different processing sizes and wall thicknesses, which ensures the qualified

ratio and high precision.

10、Oil cooling system ensures long time running every day.

11、CE approved and ISO 9001: 2008 certified.

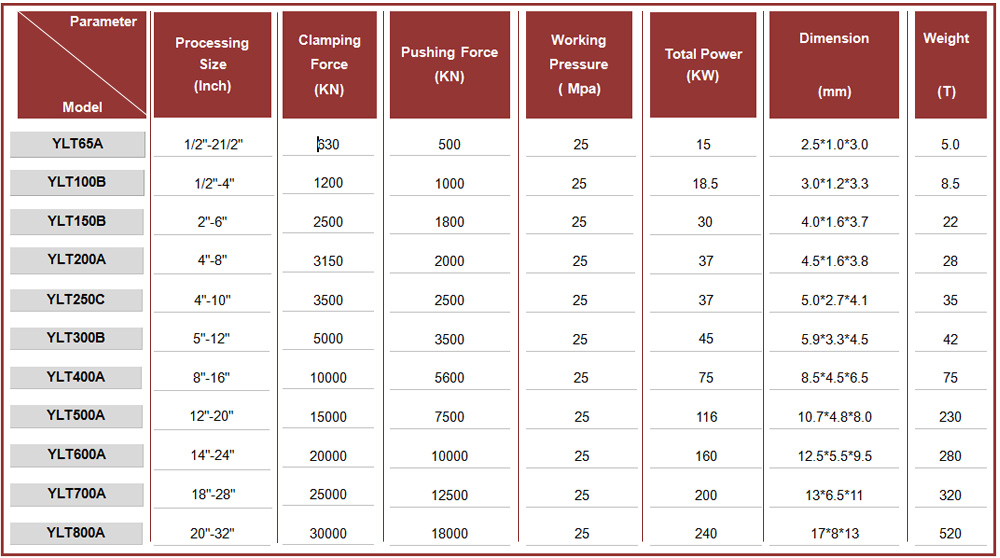

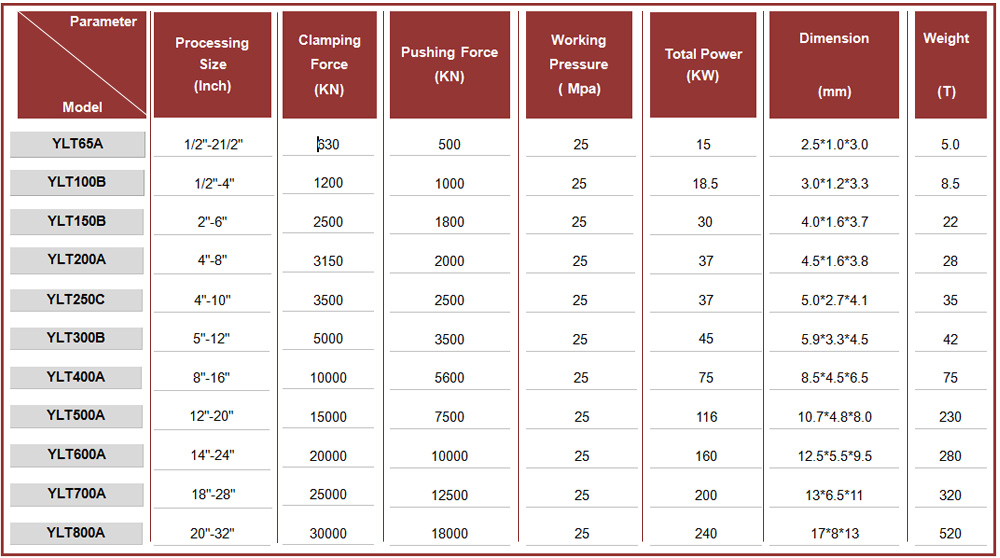

TABLE PARAMETER :